Swell Sizes and Options

SWELL: Half round foam-core panels that are available in 5 standard sizes.

Standard maximum length is 10 feet

Available in custom sizes from 2” – 10” wide.

The crown measurement below represents the maximum depth from the back of the panel

PANEL SIZES

Width Crown

2” 2 3/8″

4” 2 3/8″

4″ 1 3/8″

6” 2 3/8″

8” 2 3/8″

10” 2 3/8″

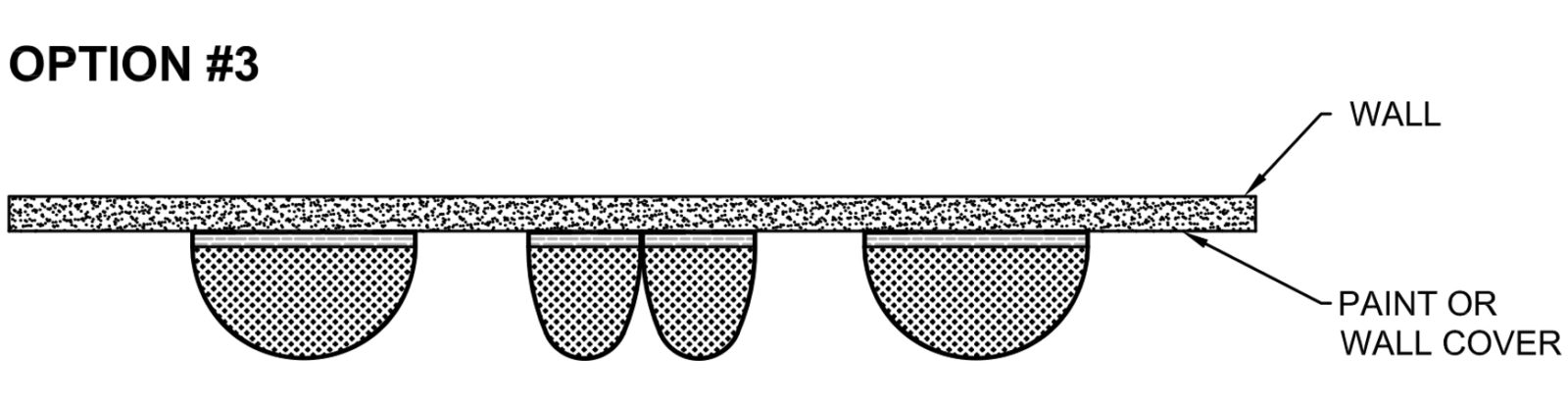

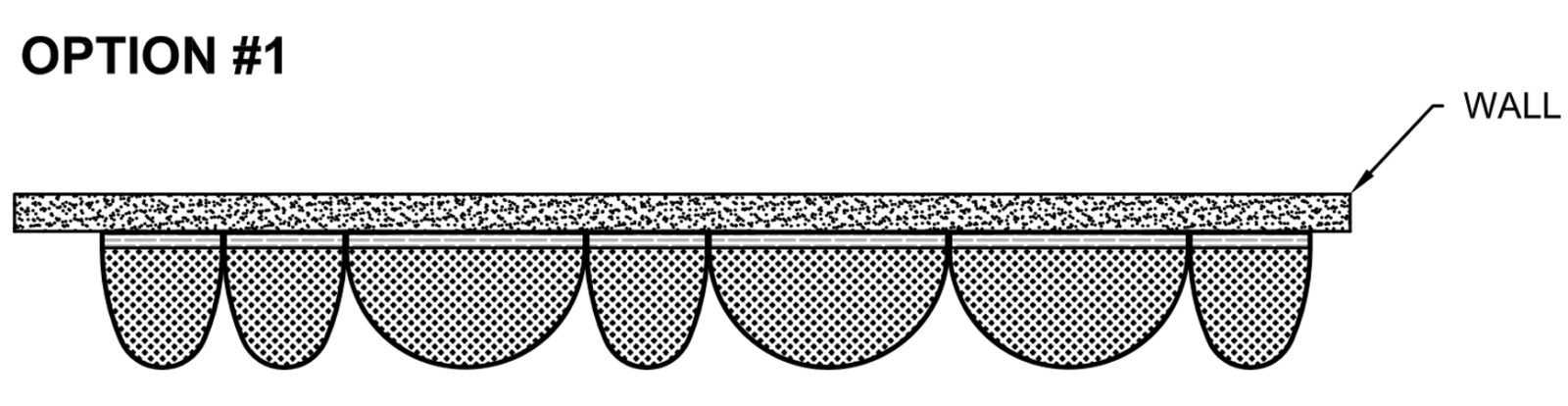

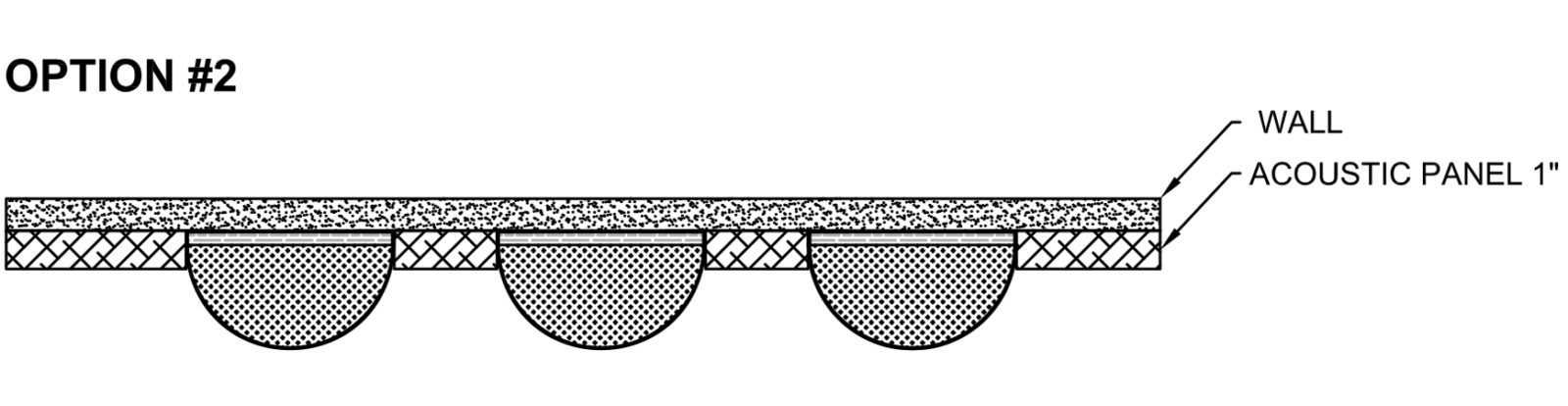

Configuration Options

Option #1… Contours are installed continuous butting so the full elevation is covered. Contours can run vertically or horizontally creating a highly acoustical wall

Option #2… Contour panels are installed on the face of a 3/4” or 1” fabric wrapped acoustical panel. The spacing or butting of the contour panels are based on your design. Contours can only run vertically creating a highly acoustical wall

Option #3…Contour panels are installed between the ¾” or 1” fabric wrapped acoustic panels. The fabric wrapped panels can be cut from 12” – 48” wide based on the design. The spacing or butting of the contour panels are based on your design. Contours can only run vertically creating a highly acoustical wall.